Home > News

> News Information

Home > News

> News Information

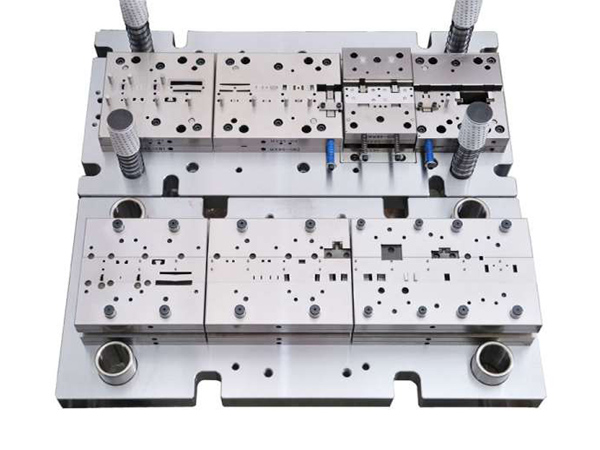

A punching die is a mold used in the punching process. There are many structural types of punching dies, and for ease of research, punching dies can be classified according to their different characteristics.

1. According to the nature of the process, it can be divided into cutting dies, punching dies, cutting dies, cutting dies, edge cutting dies, and cutting dies.

2. According to the combination of processes, it can be divided into single process molds, composite molds, and progressive molds.

3. According to the guiding methods of the upper and lower molds, they can be divided into unguided open molds and guided guide plate molds, guide column molds, guide tube molds, etc.

4. According to the materials of convex and concave molds, they can be divided into hard alloy stamping dies, steel skin stamping dies, zinc based alloy stamping dies, polyurethane stamping dies, etc.

5. According to the structure and arrangement of convex and concave molds, they can be divided into integral molds and inlay molds, positive molds and inverted molds.

6. According to the degree of automation, it can be divided into manual operation mode, semi-automatic mode, and automatic mode.

There are many classification methods, and the above classification methods reflect the different characteristics of mold structures from different perspectives. Analyzed the structure and characteristics of various punching dies through process combination.

Single process punching die

A single process punching die refers to a punching die that completes only one punching process in one stroke of a press machine, such as a feeding die, punching die, cutting die, cutting die, edge cutting die, etc.

(1) Material dropping mold

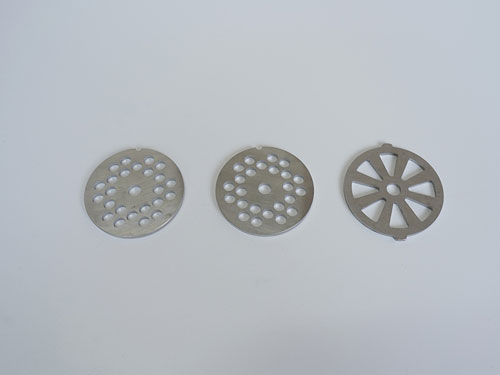

There are three common forms of drop molds:

1. The characteristics of the unguided open type feeding die are that the upper and lower dies are unguided, with a simple structure and easy manufacturing. The punching gap is determined by the guiding accuracy of the punch slider. Cutting can be completed using leftover materials from corners. Commonly used in the production of small batch stamped parts with thick materials and low precision requirements.

2. The guide plate type feeding die fits the convex die with a gap of H7/h6 between the guide plate (also a fixed discharge plate), which is smaller than the punching gap. During the return journey, the convex mold is not allowed to leave the guide plate to ensure its guiding function. Compared to open molds, it has higher precision and longer mold life, but is more complex to manufacture and often uses simple stamped parts with a material thickness greater than 0.3 millimeters.

3. The upper and lower molds are guided by guide columns and guide sleeves, ensuring easy clearance. In addition, the mold adopts a structure of elastic unloading and ejection, and the material is separated by pressing up and down during stamping. The parts have small deformation and high flatness. This structure is widely used in metal parts with small material thickness and flatness requirements, as well as non-metallic parts that are prone to delamination.

(2) Punching die

The structure of the punching die is similar to that of a general blanking die. However, punching dies have their own characteristics, especially for small hole punching dies, which must consider the strength and stiffness of the punch and the structure for quickly replacing the punch. When punching holes on the side walls of molded parts, a mechanism needs to be designed to change the horizontal direction of the punch.

1. Punch side hole mold

There are two methods for punching holes on the side walls of formed parts. One is to use a cantilever concave die structure, which can be used for punching holes, grooves, etc. on the side walls of cylindrical parts. The billet is inserted into the concave mold body, and the axial position is controlled by the positioning ring. By using this structure, multiple holes can be punched on the side wall. When punching multiple holes, the indexing and positioning mechanism should be considered structurally. The second method is to push the slider through the inclined wedge fixed on the upper mold, causing the convex mold to move horizontally, completing processes such as punching holes, grooves, and cuts on the side walls of cylindrical or U-shaped parts.

The return stroke of the wedge is completed by rubber or spring. The working angle α of the wedge is 40 °~45 °. The 40 ° inclined wedge slider mechanism has higher mechanical efficiency, and the 45 ° movement distance of the slider is equal to the stroke of the inclined wedge. For punched parts with high punching force, α can be set to 35 ° to increase horizontal thrust. The convex mold of this structure is usually symmetrically arranged, which is very suitable for punching symmetrical holes in the wall.

2. Small hole punching die

The mold structure adopts the method of shortening the length of the convex mold to prevent it from bending, deforming and breaking during the punching process. By adopting this structure, the manufacturing capability is relatively high and the service life of the convex mold is longer. This pair of molds uses impact blocks to impact the punch for punching work. The small convex mold is guided by a small pressure plate, which is guided by two small guide columns. When the upper mold descends, the large pressure plate and the small pressure plate successively press the workpiece, and the upper end of the small convex mold exposes the upper plane of the small pressure plate. The compression spring of the upper mold continues to descend, and the impact block impacts the convex mold to punch the workpiece. The unloading work is completed by the large pressure plate. The holes in the concave mold of the thick material punching small hole mold must be unobstructed to prevent waste from blocking and damaging the convex mold. The punched part is positioned on the concave die through a positioning plate, and the rear pressure block makes the punched part tightly adhere to the positioning surface.

Composite punching die

A mold that completes multiple stamping processes simultaneously in the same part of the mold during one working stroke of a press is called a composite punching die. The difficulty of composite mold design is how to arrange several pairs of convex and concave molds reasonably in the same working position.

The basic structure of the blanking punching composite mold is as follows: one side of the mold is a blanking concave mold, and the middle is a punching convex mold; On the other hand, the shape of the convex concave die is a convex die for cutting materials, and the inner hole is a concave die for punching holes. If the feeding concave mold is installed on the upper mold, it is called an inverted composite mold; On the contrary, it is called a sequential composite mold.

The characteristics of composite molds are: compact structure, high productivity, high precision of parts, especially easy to ensure the position of part holes in the shape. On the other hand, the complex structure of composite molds requires high precision for mold parts and mold assembly.

Progressive punching die

Progressive die (also known as continuous die or skip die) refers to a stamping die in which a press machine completes multiple stamping processes simultaneously at several different positions on the mold during one stroke. The formation of the entire component is gradually completed during the step-by-step process. Progressive forming is a centralized process method that enables various processes such as edge cutting, cutting, grooving, punching, plastic forming, and material dropping to be completed on a single mold. Progressive molds can be divided into ordinary progressive molds and multi station precision progressive molds.

When using a progressive die for stamping, the punched parts are gradually formed at several different positions, so to control the relative positional accuracy of the holes and shapes of the punched parts, the feeding steps must be strictly controlled.

.jpg)