Home > News

> News Information

Home > News

> News Information

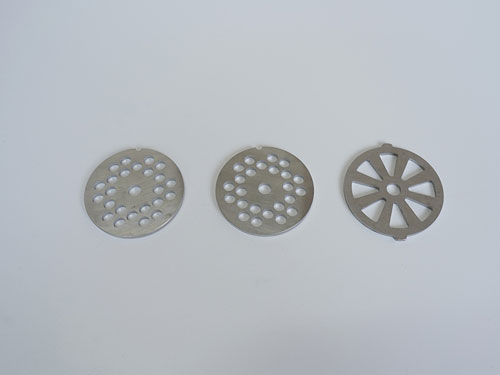

Stamping is a forming method that applies external force to sheets, strips, pipes, and profiles through a press and mold, causing them to undergo plastic deformation or separation, in order to obtain the desired shape and size of the workpiece, including cutting, bending, stretching, forming, precision machining, etc. Stamping process and molds, stamping equipment and stamping materials constitute the three elements of stamping process, and only by combining them can stamped parts be obtained. According to the application and process characteristics of precision metal stamping parts, they can be divided into various types.

1、 What are the common precision metal stamping parts

1. Automotive parts: mainly including automotive structural components, automotive functional components, automotive lathe components, automotive relays, etc.

2. Electronic components: mainly including connection devices, connectors, brush components, electrical terminals, elastic components, etc.

3. Home appliance parts: mainly including large household appliance parts, such as color tube electron gun parts, small household appliance parts, various structural and functional parts, etc.

4. IC integrated circuit lead frame: mainly includes discrete device lead frame and integrated circuit lead frame, etc.

5. Motor iron core: mainly includes single-phase series excited motor iron core, single-phase household motor iron core, single-phase shielded pole motor iron core, permanent magnet DC motor iron core, industrial motor iron core, plastic sealed stator iron core, etc.

6. Electrical iron core: mainly includes E-type transformer iron core, EI type transformer iron core, I-shaped transformer iron core, other transformer iron chips and other transformer iron sheets.

7. Heat exchanger fins: mainly including industrial heat exchanger fins, household heat exchanger fins, automotive heat exchanger fins, etc.

8. Other parts: mainly including instrumentation, IT, acoustics and photography, modern office use, and daily hardware.

2、 The advantages of precision stamping processing

1. Stamping production has high efficiency, easy operation, and is easy to achieve mechanization and automation. This is because stamping relies on stamping molds and stamping equipment to complete the processing. The stroke frequency of a regular press can reach dozens of times per minute, while high-speed pressure can reach hundreds or even thousands of times per minute. In addition, one punch can be obtained in each stamping stroke.

2. When stamping, because the die ensures the size and shape accuracy of the stamping parts, the surface quality of the stamping parts will not be damaged generally, the die life is generally long, the stamping quality is stable, the interchangeability is good, and it has the characteristics of "identical".

3. Stamping can process parts with a wide range of sizes and complex shapes, such as small stopwatches for clocks, large car longitudinal beams, covers, etc. In addition, besides the cold deformation and hardening effects of the material during the stamping process, the stamping strength and stiffness are also relatively high.

4. Stamping generally has no debris or materials, consumes less materials, and does not require other heating equipment. It is a material saving and energy-saving processing method, and the cost of stamping parts is relatively low.

3、 Common problems in precision stamping processing

Common problems in metal stamping processing include: deformation and burrs of precision stamping parts; Cracks, warping, surface scratches, angular deformations, etc. of bent parts. The flange wrinkling, wrinkling of the deep drawing wall, damage to the deep drawing wall, tearing, etc. of the deep drawing part; Flanging cracks, uneven bulging, etc.

The solution to common problems: Mold design should have reasonable clearance values between convex and concave molds, corner radii, and machining accuracy. When designing bending molds, effective measures should be taken to reduce springback and subtract the amount of springback from the mold; Design reasonable rounded corners to prevent bending and cracking. During deep drawing, the edging ring is used to prevent wrinkling, and the pressure should be moderate; Proper lubrication to reduce pulling resistance, prevent mold adhesion or workpiece tearing through; Use professional stamping oil that meets the process requirements.

.jpg)